AngrySailor

Well-Known Member

- Joined

- Dec 1, 2024

- Messages

- 68

- Reaction score

- 91

Hey guys first post checking in. Working on my early 70’s Hondo true flat which I’ve owned for near 20 years now but only hit the water again this past summer after work/moving/life put a hold on things for near 15 years... I’m making some big changes so figured I’d sign up and absorb some advice/knowledge.

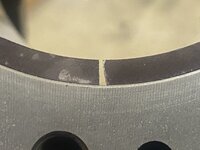

The boat was gutted and new floors/stringers installed back in the early 2000’s, I rigged her up back then from a bare hull with an 800hp 489 BBC. She’s a 10* boat, engine forward (two seater) and has an 11 1/4” 15p steel two blade prop with 18% gears in the casale split case box.

The V-drive is a 12* box so the engine was rigged to compensate however it looked bad. I ran it back in the day like this but hated the look. Obviously a 10* box is the solution but this past summer I dropped the engine level and gave her a shot with a mild 454. I noticed no vibration or issues but she would only haul 6300rpm with that engine.

I’m currently in the process of building a blown/injected gas 598 BBC so I figure I need to change things up prop and/or gear wise as the 489 would blow the prop to 7200rpm on the hit. I’ve been in touch with JJ at Beaver Fab who I see posts here occasionally and he’s been very helpful. I’m planning to source some gears and a prop release kit from Beaver Fab this winter which now has me wondering if I should source parts for a 10* box or just roll with the 12* as it doesn’t seem to be an issue. Also is it just a matter of changing the case halves and using my internals or are the guts different? (gears are obviously different). I see some empty case halves on eBay occasionally...

I have no idea who’s prop I have but I discussed a swap to 25% or 29% gears with JJ and testing with my current prop. That’s a good cost effective option however I’m not against changing the prop either. I was considering the Ron Hill 11 1/4x16p as an option and am just looking for any input from those running similar rigs. It’s my understanding that prop rpm works better than increased pitch? My main concern is holding the 598 below 7400rpm on the whack. It should be a solid 1000+hp with a 14-71 and Enderle injection.

This is a Non competition boat but will see lots of 1/4 mile hits and some river cruising usually at 60+ mph, I am more interested in being 100+mph capable than cruising efficiency so a three blade doesn’t seem like a good option. I have NO vibration issues with the boat in either previous engine combination or angle at the moment.

Just putting the feelers out for possible parts and suggestions. I’ll see if I can figure out how to post a few pics. (Don’t make fun of my POS trailer... Its on the list to fix and tandem axle swap. I had to cut it apart and shoved the boat and trailer into a 26’ UHAUL van then tetrised half my shop stuff in with it. Hauled it 1200miles to its new home)...

Thanks guys

The boat was gutted and new floors/stringers installed back in the early 2000’s, I rigged her up back then from a bare hull with an 800hp 489 BBC. She’s a 10* boat, engine forward (two seater) and has an 11 1/4” 15p steel two blade prop with 18% gears in the casale split case box.

The V-drive is a 12* box so the engine was rigged to compensate however it looked bad. I ran it back in the day like this but hated the look. Obviously a 10* box is the solution but this past summer I dropped the engine level and gave her a shot with a mild 454. I noticed no vibration or issues but she would only haul 6300rpm with that engine.

I’m currently in the process of building a blown/injected gas 598 BBC so I figure I need to change things up prop and/or gear wise as the 489 would blow the prop to 7200rpm on the hit. I’ve been in touch with JJ at Beaver Fab who I see posts here occasionally and he’s been very helpful. I’m planning to source some gears and a prop release kit from Beaver Fab this winter which now has me wondering if I should source parts for a 10* box or just roll with the 12* as it doesn’t seem to be an issue. Also is it just a matter of changing the case halves and using my internals or are the guts different? (gears are obviously different). I see some empty case halves on eBay occasionally...

I have no idea who’s prop I have but I discussed a swap to 25% or 29% gears with JJ and testing with my current prop. That’s a good cost effective option however I’m not against changing the prop either. I was considering the Ron Hill 11 1/4x16p as an option and am just looking for any input from those running similar rigs. It’s my understanding that prop rpm works better than increased pitch? My main concern is holding the 598 below 7400rpm on the whack. It should be a solid 1000+hp with a 14-71 and Enderle injection.

This is a Non competition boat but will see lots of 1/4 mile hits and some river cruising usually at 60+ mph, I am more interested in being 100+mph capable than cruising efficiency so a three blade doesn’t seem like a good option. I have NO vibration issues with the boat in either previous engine combination or angle at the moment.

Just putting the feelers out for possible parts and suggestions. I’ll see if I can figure out how to post a few pics. (Don’t make fun of my POS trailer... Its on the list to fix and tandem axle swap. I had to cut it apart and shoved the boat and trailer into a 26’ UHAUL van then tetrised half my shop stuff in with it. Hauled it 1200miles to its new home)...

Thanks guys

Attachments

-

F2D5C51A-8F4A-450A-9BCA-E666379B35F5.jpeg2.3 MB · Views: 0

F2D5C51A-8F4A-450A-9BCA-E666379B35F5.jpeg2.3 MB · Views: 0 -

AD8B0E65-CF46-45EA-ADCB-7E17EB888178.jpeg326.4 KB · Views: 0

AD8B0E65-CF46-45EA-ADCB-7E17EB888178.jpeg326.4 KB · Views: 0 -

AB81781D-AA2D-4606-99E0-E5AD22899CE2.jpeg2.7 MB · Views: 0

AB81781D-AA2D-4606-99E0-E5AD22899CE2.jpeg2.7 MB · Views: 0 -

6AB99E67-EF4F-4D0C-8D5C-59AC372206F9.jpeg2.2 MB · Views: 0

6AB99E67-EF4F-4D0C-8D5C-59AC372206F9.jpeg2.2 MB · Views: 0 -

A4B7109E-33CD-419B-8EAE-33174AE574C6.png5.1 MB · Views: 0

A4B7109E-33CD-419B-8EAE-33174AE574C6.png5.1 MB · Views: 0 -

36EB2CD0-F037-402F-96D6-B5F226CC9F3C.jpeg2.9 MB · Views: 0

36EB2CD0-F037-402F-96D6-B5F226CC9F3C.jpeg2.9 MB · Views: 0 -

5A2F8905-298F-4470-9D4D-7A20BB788D7C.jpeg195 KB · Views: 0

5A2F8905-298F-4470-9D4D-7A20BB788D7C.jpeg195 KB · Views: 0