CigAjerk

Well-Known Member

- Joined

- Dec 22, 2011

- Messages

- 745

- Reaction score

- 834

You guys have always been great about solutions and I have a problem...

I got a call a few years ago about replacing some egress basement window wells in Tempe. I got the call because they tried "other" companies and the other companies will only do demo/excavation with excavator. Due to AC units, pools, block walls and few other obstacles hand dig was the homeowners focus. I gathered my demo crew and we assessed. Home owner agreed to more of a T&M for the project and we were off.

Homeowner and I start bullshitting about how and why it failed. I saw 2 problems, the failure was at the top corners and the runoff from the pool deck caused the ponding/failure And #2, galvy just doesn't like things here. Once the coating is gone the rust starts. The homeowner requested formed fiberglass wells. The nice part is, supplier provided engineering, egress ladders are built-in, covers are a lot lighter (powder coated aluminum). The theory is fiberglass will out last the corrugate but that's just a theory at this point.

First home owner is so pleased with the work we did he calls original contractor (who apparently installed every basement window well in the valley when the homes were built). Tells original contractor I banged it out and was reliable. Now original contractor refers all the people who call him to call me for repair/replacement if it's a candidate for hand dig.

Since the first call it's been a really good gig. My guys board up the windows, cover the drains, cut out the old well. New crew comes in and shapes. They also excavate extra on the sides to allow for reinstallation to hammerdrill and anchor into the basement walls. They set the wells, I verify placement and I'm on my way. Crew backfills/compacts and cleans up DG, pavers or whatever we needed to move to handle the replacement.

I have only seen wells that are 66" wide by 96" tall. I've replaced a bunch and walked even more. The jobs I didn't get were the people that want to patch and not replace. I'm not comfortable with patching and I don't offer solutions I cannot warrant. I walked a house yesterday that has 79" Wide x 96" Tall wells.

THE PROBLEM- Fiberglass supplier only makes 66" wide wells. A few different metal suppliers have responded to me and it appears they've all stopped 96" tall product and max height is now 84". 84" won't work cause I can't raise the bottom of the well. Egress windows dictate the "bottom" of the well and existing grade dictates the height. Any replacement needs to be 96" period.

Another problem, this particular failure is completely different than all the other wells I've seen. This is not failing from inadequate drainage. The failure on these particular well is happening down low. 5 wells, all on the same side of the house all failing at the same lower level. Condensation? I know the wells aren't filling to that height, sump pump and drains all operating properly and windows would leak with that much water.

Solutions I've discussed with different homeowner but haven't explored for multiple reasons.

1. Leave existing wells in place, clean up failing areas, make a form slightly inside and pour coating/epoxy something utilizing the form.

2. Leave existing wells in place, dig around outside about 12". Cover the backside, drop in a rebar cage, pour concrete. Demo metal after curing. Doweling into house would be a bit of issue due to the existing well flange.

The failures are all happening in the 15-20 years after build and the calls I'm getting are more frequent.

Any engineers or other contractors who have ideas is extremely welcome right now.

I got a call a few years ago about replacing some egress basement window wells in Tempe. I got the call because they tried "other" companies and the other companies will only do demo/excavation with excavator. Due to AC units, pools, block walls and few other obstacles hand dig was the homeowners focus. I gathered my demo crew and we assessed. Home owner agreed to more of a T&M for the project and we were off.

Homeowner and I start bullshitting about how and why it failed. I saw 2 problems, the failure was at the top corners and the runoff from the pool deck caused the ponding/failure And #2, galvy just doesn't like things here. Once the coating is gone the rust starts. The homeowner requested formed fiberglass wells. The nice part is, supplier provided engineering, egress ladders are built-in, covers are a lot lighter (powder coated aluminum). The theory is fiberglass will out last the corrugate but that's just a theory at this point.

First home owner is so pleased with the work we did he calls original contractor (who apparently installed every basement window well in the valley when the homes were built). Tells original contractor I banged it out and was reliable. Now original contractor refers all the people who call him to call me for repair/replacement if it's a candidate for hand dig.

Since the first call it's been a really good gig. My guys board up the windows, cover the drains, cut out the old well. New crew comes in and shapes. They also excavate extra on the sides to allow for reinstallation to hammerdrill and anchor into the basement walls. They set the wells, I verify placement and I'm on my way. Crew backfills/compacts and cleans up DG, pavers or whatever we needed to move to handle the replacement.

I have only seen wells that are 66" wide by 96" tall. I've replaced a bunch and walked even more. The jobs I didn't get were the people that want to patch and not replace. I'm not comfortable with patching and I don't offer solutions I cannot warrant. I walked a house yesterday that has 79" Wide x 96" Tall wells.

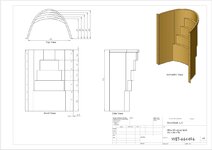

THE PROBLEM- Fiberglass supplier only makes 66" wide wells. A few different metal suppliers have responded to me and it appears they've all stopped 96" tall product and max height is now 84". 84" won't work cause I can't raise the bottom of the well. Egress windows dictate the "bottom" of the well and existing grade dictates the height. Any replacement needs to be 96" period.

Another problem, this particular failure is completely different than all the other wells I've seen. This is not failing from inadequate drainage. The failure on these particular well is happening down low. 5 wells, all on the same side of the house all failing at the same lower level. Condensation? I know the wells aren't filling to that height, sump pump and drains all operating properly and windows would leak with that much water.

Solutions I've discussed with different homeowner but haven't explored for multiple reasons.

1. Leave existing wells in place, clean up failing areas, make a form slightly inside and pour coating/epoxy something utilizing the form.

2. Leave existing wells in place, dig around outside about 12". Cover the backside, drop in a rebar cage, pour concrete. Demo metal after curing. Doweling into house would be a bit of issue due to the existing well flange.

The failures are all happening in the 15-20 years after build and the calls I'm getting are more frequent.

Any engineers or other contractors who have ideas is extremely welcome right now.