530RL

Well-Known Member

- Joined

- Sep 18, 2012

- Messages

- 21,795

- Reaction score

- 20,959

D, E and F models.

We are working on a D model and it has a round nose and a 420 shaft horse power motor. An E model has a pointed nose and the option of a C20B engine at 420 shaft horsepower or a C20R which is 450 shaft horsepower. The R makes more power when you are high in altitude or hot. Despite thoughts to the contrary, R model engines do not make much more power at sea level and are quite a bit more expensive to maintain.

An F model has major changes. Although it has an identical fuselage, it has longer main rotor blades, a larger tail rotor, stronger tail boom, tail boom extension and a C30 engine which makes 650 shaft horsepower. This model rarely is limited by turbine power but is limited by maximum amount of torque through the rotor system.

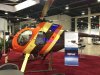

This is a picture of the F model tail boom and extension.

Because the engine is significantly bigger, it is jammed into the same engine compartment and has a significantly larger exhaust stack. It is a bitch to work on and you need an A&P with small hands and thin fingers to get at a lot of stuff.

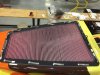

Due to the larger engine size and length, the rear clamshells are modified with lower fairings to cover the bottom of the engine and allow it to fit.

We are working on a D model and it has a round nose and a 420 shaft horse power motor. An E model has a pointed nose and the option of a C20B engine at 420 shaft horsepower or a C20R which is 450 shaft horsepower. The R makes more power when you are high in altitude or hot. Despite thoughts to the contrary, R model engines do not make much more power at sea level and are quite a bit more expensive to maintain.

An F model has major changes. Although it has an identical fuselage, it has longer main rotor blades, a larger tail rotor, stronger tail boom, tail boom extension and a C30 engine which makes 650 shaft horsepower. This model rarely is limited by turbine power but is limited by maximum amount of torque through the rotor system.

This is a picture of the F model tail boom and extension.

Because the engine is significantly bigger, it is jammed into the same engine compartment and has a significantly larger exhaust stack. It is a bitch to work on and you need an A&P with small hands and thin fingers to get at a lot of stuff.

Due to the larger engine size and length, the rear clamshells are modified with lower fairings to cover the bottom of the engine and allow it to fit.

Last edited: